ABC TILE ADHESIVE LOW-DUST is a cement-based adhesive specifically formulated for cleaner & mess-free tile installations on concrete surfaces. High quality aggregates and selected chemical additives are used strictly conforming to International Standards.

Renovations and tile installations on concrete surfaces that require less dust when mixing (high rise buildings, condominiums, hospitals, kitchens, etc.). For all sizes of earthenware tiles (ceramic & clay tiles) & mosaic tiles (porcelain & stoneware mosaic).

PROPERTIES

- Low-dust (cleaner tile installation)

- Fast & easy application & installation

- Professional finish & excellent workmanship

- High tensile adhesive strength (200 PSI)

- High performance

- Easy to trowel (achieve 100% mortar coverage for best results)

- High shear strength (withstands minor structural movements caused by moving loads)

- Resistant to thermal deformation (adapts to temperature change)

- Economical (high productivity, achieve more in less time)

- Eco-friendly (low volatile organic compound levels)

The surface must be fully cured, structurally stable, level, clean and free of paint and contaminants such as dirt, dust, loose material, oils, chemicals, etc.

| Substrate | Surface Preparation |

|---|---|

| New concrete | Concrete must have fully cured (28 days) |

| Waterproofed concrete | Cementitious waterproofing must have cured 3 days (conduct flood/leak test if needed) |

| Painted concrete | Abrade paint (w/ steel brush and paint remover) |

| Smooth concrete | Apply scratch coat to roughen surface |

| Repair work | Remove old loose tile & concrete mortar |

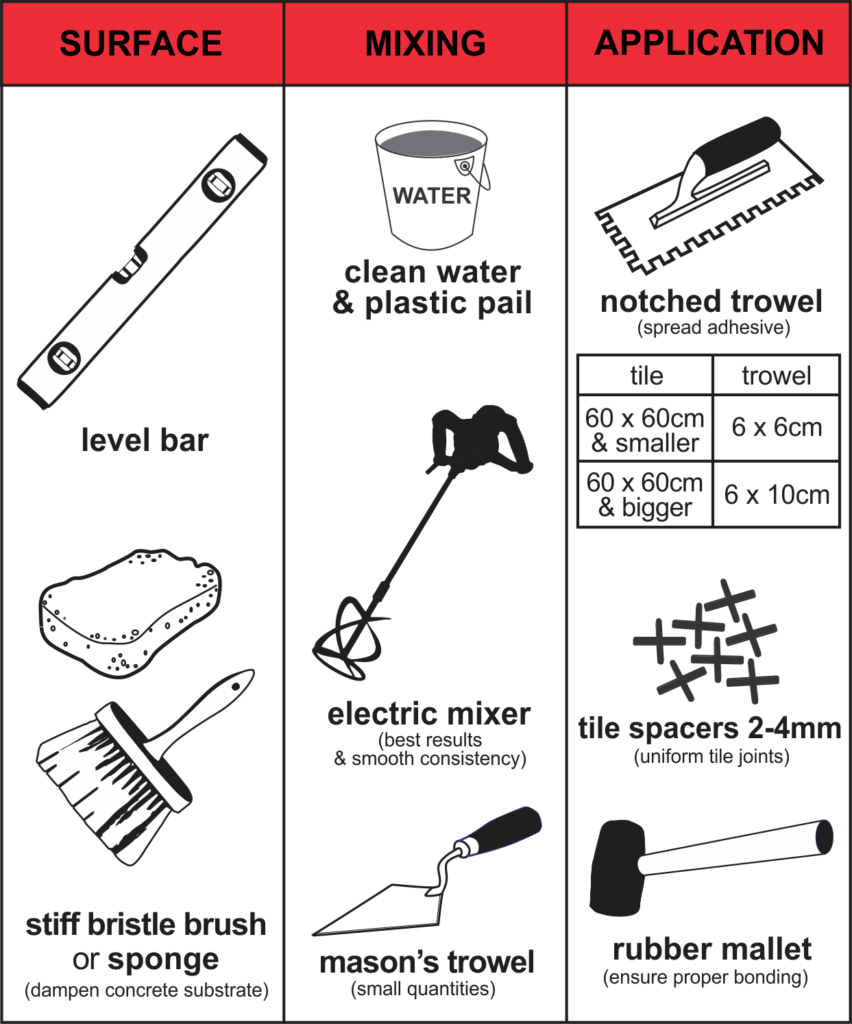

TOOLS

COVERAGE

| COVERAGE of 25kg Tile Adhesive Low-Dust (approx) | ||

|---|---|---|

| Tile Size | Adhesive Thickness | Area |

| 30 x 30cm & smaller and mosaic tiles | 3 mm | 5 m² |

| 60 x 60cm & smaller | 6 mm | 2.6 m² |

| NOTE: Coverage is dependent on tile size, surface smoothness of the back of the tile, substrate condition and adhesive application thickness. The bigger the tile, the smaller the coverage area. | ||

How to use ABC Tile Adhesive Low-Dust

1. Mixing (Mix in plastic pail)

| MIXING RATION | ||

|---|---|---|

| Method | Water | Tile Adhesive |

| Mechanical (Electric Mixer) | 5.25 L | 25 kg |

| Manual (Mason's Trowel) | 6 L | |

Pour water in a plastic pail & add Tile Adhesive Low-Dust. Mix 2-3 minutes to attain a smooth, lump-free

& pasty consistency. Let mixture rest for 15 minutes. Mix again briefly before use. (NEVER mix old batch with new batch.)

Talog: Maghalo ng Tile Adhesive Low-Dust at malinis na tubig sa timba. Haluin hanggang sa maging malapot at mawala na ang pamumuo ng tile adhesive. Maghintay ng 15 minuto bago muling haluin at gamitin. (Huwag paghaluin ang luma at bagong gawang halo.)

POT Life: 4 hours

2. Application (Apply adhesive mortar with notched trowel)

Apply tile adhesive with a notched trowel combing in a straight manner 1m2 at a time. For large format tiles or tiles with a smooth back surface, apply a scratch coat at the back of the tile & let dry before using the double spreading adhesive method.(Dampen concrete surface before adhesive application.)

Tagalog: Sa isang metro-kuwadrado kada latag, ipahid ang tile adhesive nang deretsong direksyon. Para sa mga malalaking tiles at tiles na sobrang kinis ang likuran, pahiran muna ito ng scratch coat at patuyuin bago mag-pahid ng adhesive. Ipahid ang adhesive sa likod ng tiles at sa kongkreto. (Basain ang kongkreto bago magpahid ng tile adhesive.)

3. Tile Installations (Install tiles with tile spacers & rubber mallet)

Install tiles within 20 minutes mortar open time. Use tile spacers for proper alignment. Position and adjust tiles within 15 minutes. (Foot traffic 24 hours)

Tagalog: Idikit ang tiles nang hindi lalampas ng 20 minutong open time. Pagkadikit, ayusin at ihilera ang tiles sa loob ng 15 minuto. (Foot traffic 24 hours)

Adjust tiles 15 minutes

Open time 20 minutes

TIPS:

- Do random checks if the back of the tiles are fully covered with tile adhesive.

- Check if tile adhesive mortar still adheres to your finger to find out if the open time has not lapsed. If open time has lapsed, remove old tile adhesive layer and reapply a new one to avoid bonding failure.

- NEVER add newly prepared tile adhesive to a previously mixed batch.

- Use tile spacers for uniform grout lines. A tile joint width is needed to accommodate possible tile movement due to thermal deformation, substrate shrinkage or tile expansion, thus preventing the tile from cracking.

Packaging: 25 kg multilayer paperbag

CLEANING / SAFETY / STORAGE / SHELF LIFE

Use clean water to remove excess tile adhesive on tile surface and tools before it hardens. Non-toxic. Do not inhale or ingest. As with any cementitious material, avoid eye exposure and prolonged skin contact. In case of irritation, rinse with sufficient water. If symptoms persist, consult your doctor. Store in a cool dry place. In its original unopened packaging, this will remain usable for a period of one year from date of manufacture.

WARRANTY

Due to the variety of applications, the differing methods of working, the various properties of bases, etc., we cannot assume responsibility or liability with regard to the application of our products. Our guarantee and liability is restricted to the quality of our products at the time of acceptance of the customer of such products. In no case shall our liability extend beyond replacement of defective products, if any, found at the time of acceptance. For all deliveries and services, our General Sales Condition, including warranties stipulated for each case are valid.